The Fox Farm Treehouse is full of custom built-ins and thoughtful details ranging from slab countertops to dovetail joints in the framing. Join us as we take a look back into our prefabrication shop to see what went into creating these handcrafted features.

The completed treehouse looks at home in a grove of oak trees- you can see more photos here and take our video tour here.

Elements of our “treehouse in a box” – our crew prefabricated all the walls in our shop in Washington State, before shipping them to site for assembly.

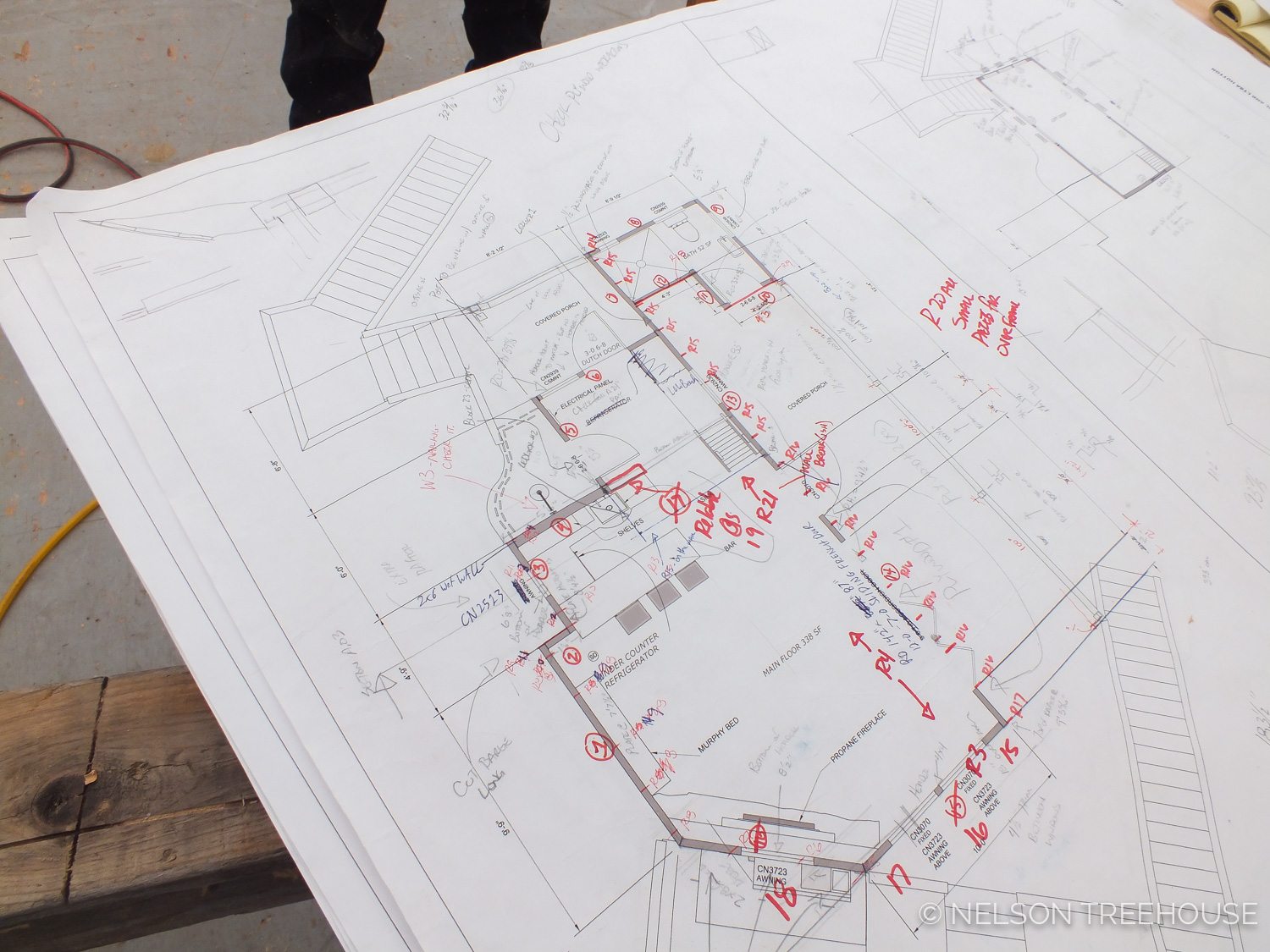

The crew used detailed shop drawings to construct the treehouse components and labeled each element to facilitate reassembly onsite.

Prefab maestros Rolf and Griffin test the structural integrity of the treehouse’s loft platform.

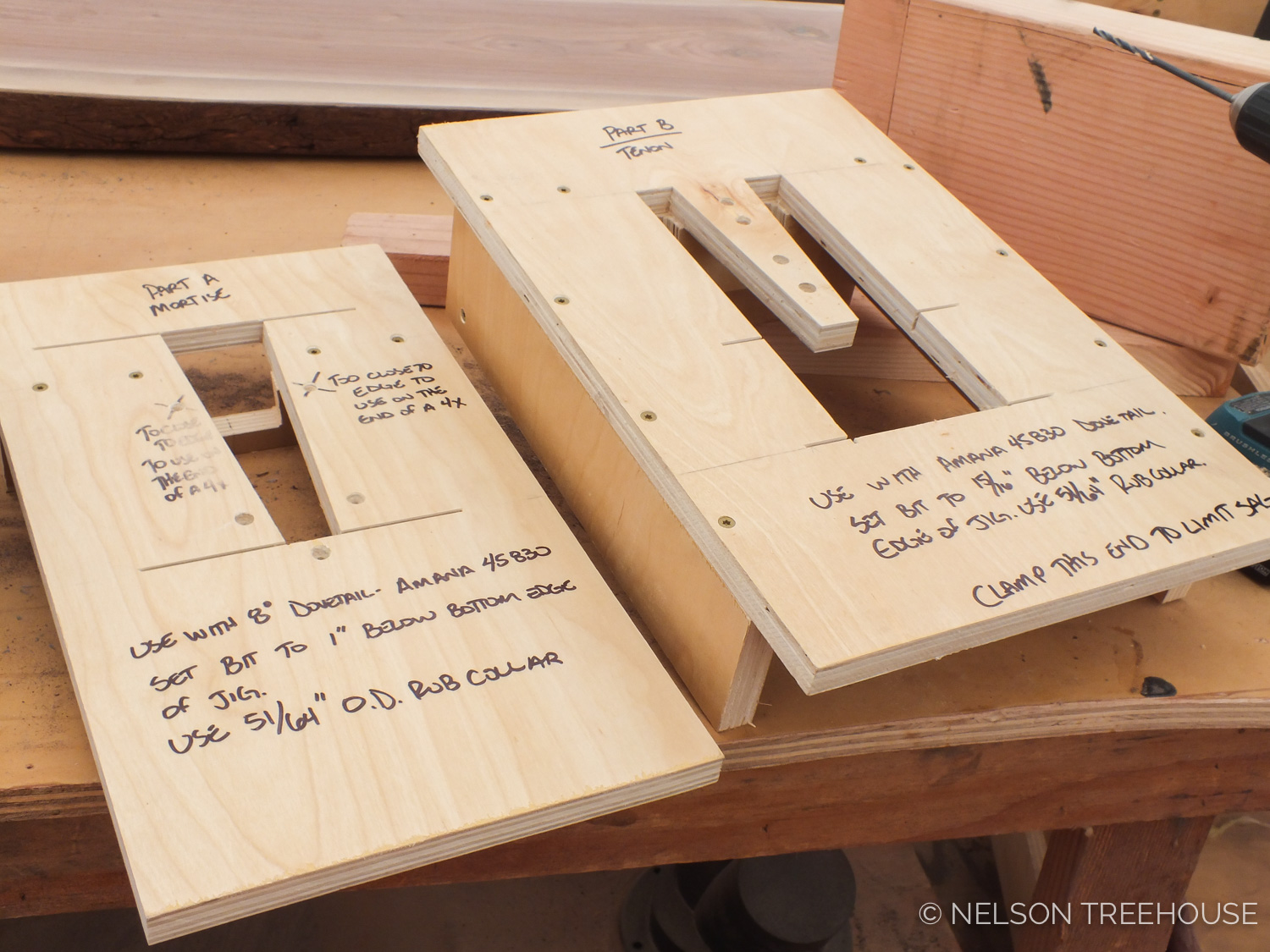

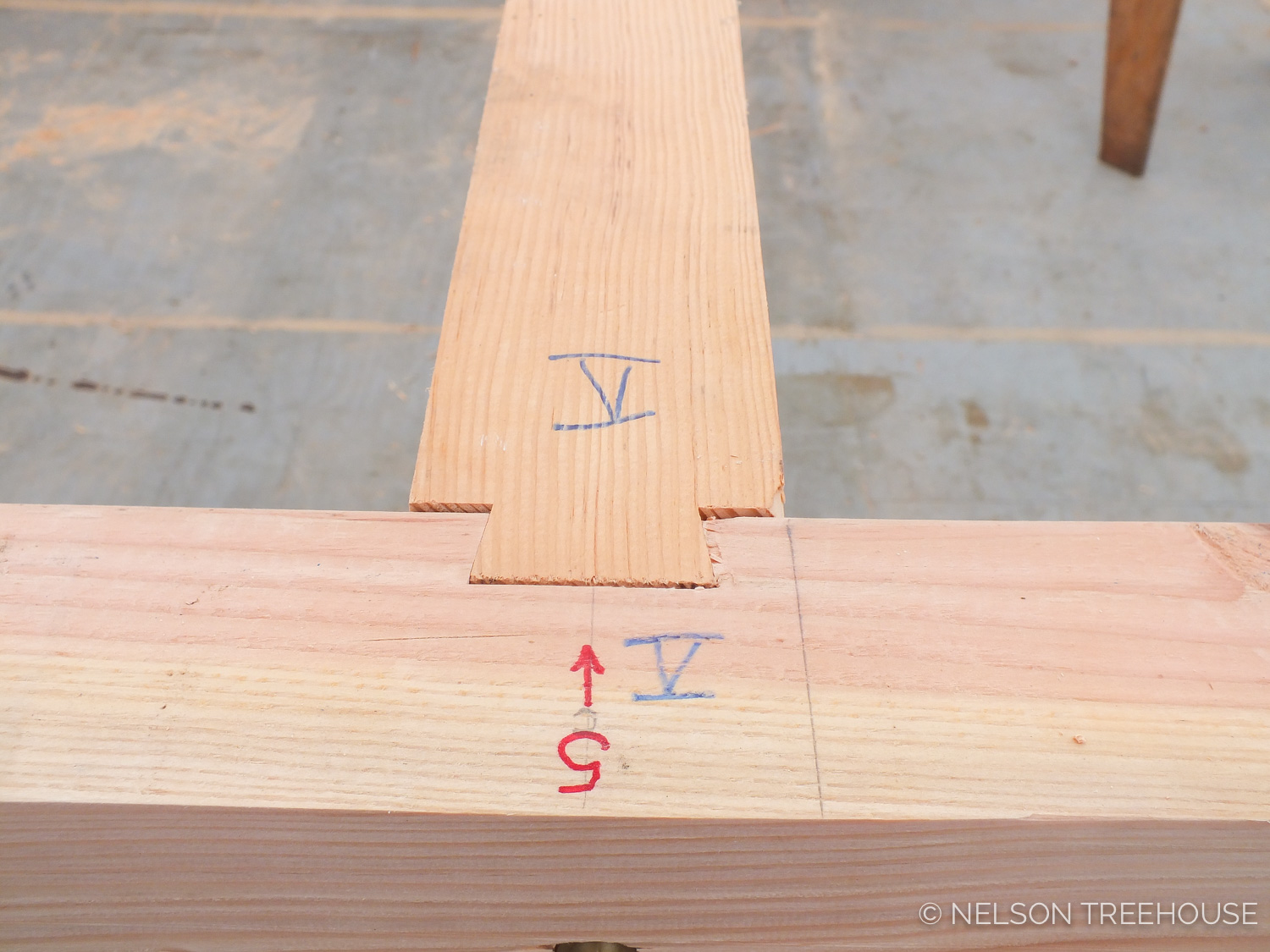

Rolf and Griffin designed a dovetail mortise and tenon jig for the loft platform – this draws the platform together for added strength.

Making this jig for dovetail mortise and tenon joints enables the prefab crew to use it again in the future.

These joints help lock the platform together.

The prefab crew assembled the loft roofline inside our shop to ensure that the components fit perfectly together. This roofline’s opening to the large common space below made it distinctive and a little tricky to construct.

The angled loft roofline inside the completed treehouse.

Dylan Rauch crafted live edge countertops from black walnut wood for the treehouse kitchen.

Dylan added this maple wood butterfly joint to hold together a large natural split in the walnut. As Dylan says, “It’s wonderful to turn what might be perceived as a defect into a unique feature of the built-in.”

The unique diamond shape of this countertop was dictated by the original piece of wood. It came from the trunk intersection of two branches of a tree. Dylan cleaned up each “leg” but made sure to keep some of the original bark on the outer rim of the slab.

The finished slab countertops add elegance to the kitchen.

PHOTO COURTESY OF SEANIX ZENOBIA

PHOTO COURTESY OF SEANIX ZENOBIA

Seanix Zenobia created the bed frame for the loft, using ash tree branches he harvested from his own backyard. Many of these branches had been damaged from emerald ash tree borers.

PHOTO COURTESY OF SEANIX ZENOBIA

PHOTO COURTESY OF SEANIX ZENOBIA

PHOTO COURTESY OF SEANIX ZENOBIA

PHOTO COURTESY OF SEANIX ZENOBIA

Although Seanix had never made a bed frame from branches before, his background in crafting log bed frames informed this project.

PHOTO COURTESY OF SEANIX ZENOBIA

PHOTO COURTESY OF SEANIX ZENOBIA

Seanix attached the top and bottom rails to the posts with coped joints, and fastened the vertical branches together using Screw Products.

To achieve a perfect fit, Seanix trimmed a few of the branches when the headboard and footboard were in place inside the loft.

Ian Franks crafted this built-in Murphy bed from cherry wood plywood – as a hardwood, cherry is ideal for furniture. Ian added live-edge cedar wood around the border of the bed and to create the illusion of two separate doors on the pull-down panel. Murphy beds are ideal for treehouses, as their foldability allows the room to do double duty as bedroom and living space.

We hope you’ve enjoyed taking a look at the prefab process behind the Fox Farm Treehouse!

To stay up-to-date on all things treehouse, subscribe to our newsletter and give us a follow on Facebook and Instagram.

To the trees!