Welcome to our treehouse HQ, where we prefabricate almost all the components for our treehouses! Step into the shop and take a look back at what went into crafting the Magical Maine Treehouse.

Prefab wizard Griffin reviews shop drawings beside stacks of walls. Each prefabricated component is carefully labeled to streamline reassembly onsite.

The Maine treehouse walls left space for many windows to frame sweeping views of the hemlock forest and nearby lake.

Here, the turret and winding staircase begin to take shape. The prefab crew will often mock up treehouse parts that are particularly complex. With the knowledge that all the pieces fit together perfectly, the prefab crew will then dissemble the mock-ups for shipment.

The crew crafted a ring beam to fit atop the turret walls. This ring beam was necessary since the walls formed only about three quarters of a circle – the ring beam completes the circle and carries the roof structure of the turret.

Prefab guru Rolf works on the ring beam.

The ring beam had to be sliced into two parts in order to fit in the shipping truck.

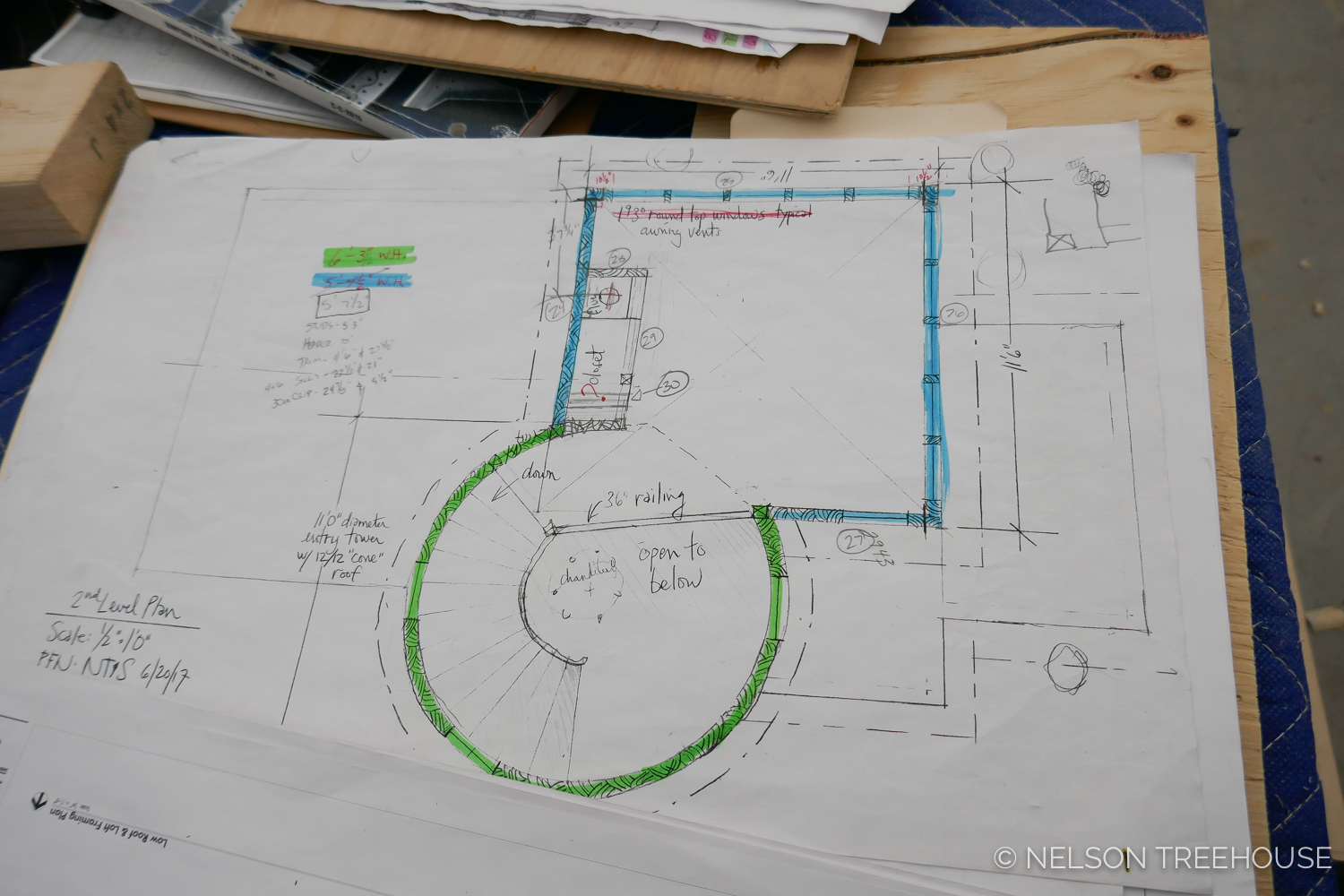

Shop drawings for the turret, winding staircase, and first floor.

Building out the skeleton for the winding staircase.

The winding staircase is comprised of Doug fir and maple wood.

Cutting strips for the staircase railing. These strips were laminated and clamped to follow the curve of the turret.

The spiral staircase in the finished treehouse.

The crew also mocked up the turret roof frame. They made sure to put it through rigorous strength testing, which naturally involved letting their kids climb on it.

This turret roof was pretty straightforward to build, as each rafter was cut at the same angle.

Griffin’s photo from the top of the turret starts to look like an optical illusion if you stare at it too long…

The completed turret looks dazzling, if we do say so ourselves!

Our master of built-ins, Dylan, crafted this dining nook table from reclaimed Doug fir wood.

Markings made by critters add character to the piece.

Dylan also created these built-in benches for the dining nook.

The dining nook inside the completed treehouse.

Geoff, one of our intrepid “Road Warriors”, shared these photos of the onsite construction process. Here, the expansive platform comes together for the 600-square-foot treehouse.

The turret is reassembled onsite – our prefab crew did a stellar job of making sure it would fit together seamlessly!

Dark wood inlays above the windows add a touch of Gothic flair. The turret was capped with a metal roof – we love the custom rafter tails that peek out from beneath it.

Geoff soaks in the build progress.

The crew made sure to put Dylan’s dining nook through a solid round of testing.

We hope you’ve enjoyed taking a look behind the scenes of the Magical Maine Treehouse – our crew put a lot of love into crafting its custom details! You can see all our photos of the completed treehouse here.

To stay up-to-date on all things treehouse, subscribe to our newsletter and give us a follow on Facebook and Instagram.

To the trees!